Silicon is the second most abundant element in Earth’s crust and one of the seven most abundant elements in the universe.

The atomic arrangement of the element in its crystal structure and its inertness, along with other physical and chemical properties, makes silicon a suitable element for a number of applications, such as optical windows.

Silicon windows are transparent materials in the MWIR region, used in optical systems to block and control the flow of light. They have diverse applications in aerospace, defense, and other industrial manufacturing processes to produce components of various devices and instruments, such as:

The silicon optical windows act as a protective barrier in optical components to shield them from dust particles or contaminants. Further, they have stable optical interfaces that enable researchers to execute high-quality imaging, measurements, and light analysis for improved data quality and accuracy in their applications.

However, to perform such high-throughput studies, you need silicon windows that meet your specifications and are superior in quality and performance.

At Lattice Materials, we manufacture custom, high-quality precision silicon windows that conform to regulatory standards—all tailored to support your optical applications.

From simple designs or intricate geometries, our team is prepared to help you speed up your product manufacturing process and reach the global market.

Optical Properties Specifications of Silicon Windows:

Material: Silicon (Si)

Moh’s Hardness: 7

Refractive Index @25℃: 3.456 @ 2 microns

Absorption Coefficient @25℃: 0.027 to 0.040*

Melting Point: 1412°C

Boiling point ℃: 2878

*Standard optical grade silicon varies with resistivity

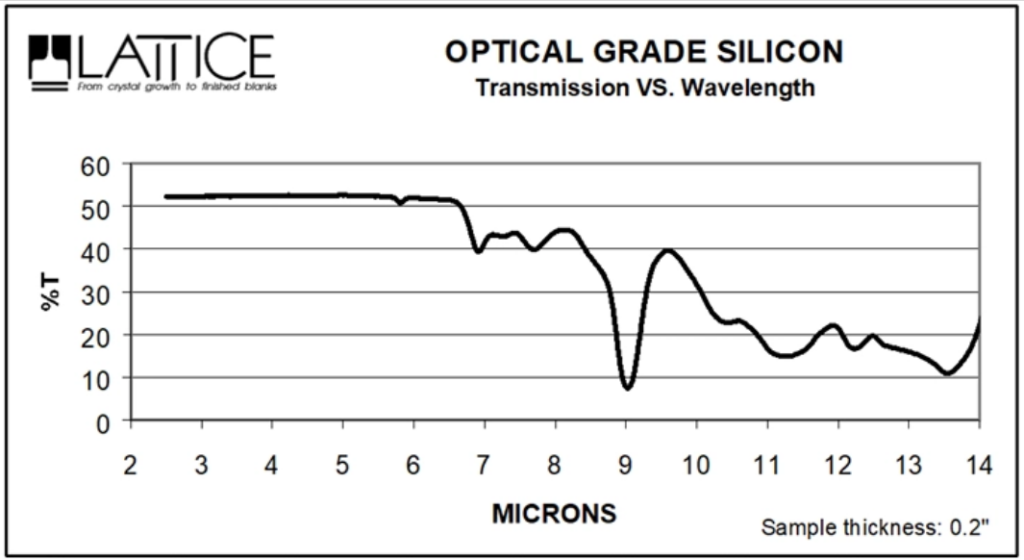

Figure: Graph showing transmission percentage of silicon.

Silicon is a lower-density element than germanium and zinc selenide and offers a good transmittance that makes it an excellent choice for developing optical systems. The 1.2 – 7μm transmittance range is especially useful for near-infrared (NIR) or mid-wave infrared (MWIR) applications.

Optical-grade silicon is commonly blended (with a resistivity of >1 Ohm-cm for N-type and >10 Ohm-cm for P-type) to avoid absorption bands within the transmission range. Further, when it comes to weight-sensitive applications, silicon is a preferred material because of its lower density than other elements, such as germanium.

This makes silicon windows perfect for affordable and lighter optical designs.

Several factors determine suitable silicon windows for different applications, which include:

At Lattice Materials, we help you get suitable silicon windows for your applications. Whatever your specifications are, our team of experts manufactures them with high precision for high performance.

Our highly skilled engineers and technicians work together to ensure that your custom silicon windows comply with quality standards and provide optimal performance in precision optics.

Contact us here and one of our team members will reach out to you to discuss more about the specifications and requirements of your applications.